Product Overview

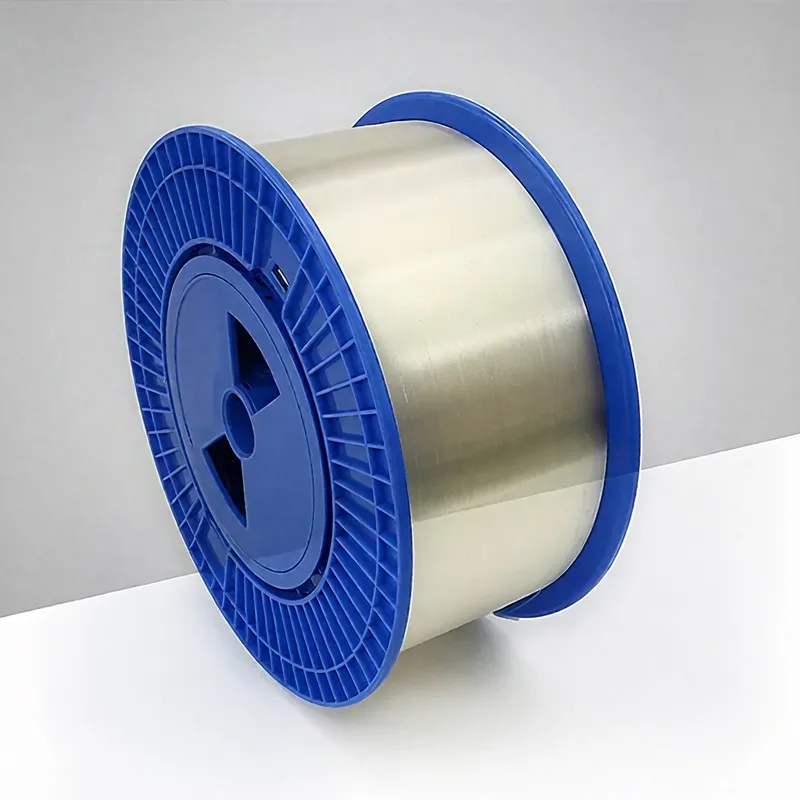

Fabricated using the Modified Chemical Vapor Deposition (MCVD) process, this standard panda-type PM fiber features a germanosilicate core surrounded by two boron-doped stress-applying parts (SAPs) that generate high linear birefringence. This structure effectively locks the polarization state of launched light, achieving polarization crosstalk of ≤ -28 dB over 1 meter at 1310 nm.

With a conventional 245 μm dual acrylate coating and precise 125 μm cladding geometry, the fiber offers excellent handling robustness, low microbending sensitivity, and compatibility with standard fusion splicers equipped with rotational alignment. Its low attenuation (≤0.8 dB/km) and tight mode field diameter control (6.0 ±0.5 μm) ensure minimal insertion loss in pigtailed devices and sensor assemblies.

Technical Specifications

| Brand Name | Winner |

| Model Number | PM1310-125-6.0/245 |

| Fiber Type | Panda-Type Polarization-Maintaining Single-Mode Fiber |

| Operating Wavelength | 1310 nm |

| Attenuation | ≤0.8 dB/km @1310 nm |

| Mode Field Diameter | 6.0 ± 0.5 μm @1310 nm |

| Cut-off Wavelength | 1100–1270 nm |

| Cladding Diameter | 125 ± 1 μm |

| Coating Diameter | 245 ± 5 μm |

| Polarization Crosstalk | ≤ -28 dB per meter @1310 nm |

| Bow (Shoot Length) | ≤ 3.0 mm per meter |

| Tension Screening Level | ≥100 kpsi |

| Manufacturing Process | Modified Chemical Vapor Deposition (MCVD) |

| Key Performance | High geometric uniformity for consistent coil winding

Low splicing loss with axis alignment (<0.2 dB typical)

Excellent thermal and mechanical stability

Compliant with Telcordia GR-20 reliability standards |

Applications

- Fiber optic gyroscopes (FOGs) for aerospace navigation and stabilization

- Polarization-maintaining couplers, isolators, and circulators

- Laser diode and fiber laser pigtails requiring polarized output

- Interferometric current and acoustic sensors

- Quantum optics and coherent communication test platforms

Integration Guidance

For optimal polarization extinction ratio (PER), align the slow axis (indicated by SAP orientation) during splicing using a rotational fusion splicer. Maintain bend radii >15 mm to avoid induced birefringence distortion. The standard 245 μm coating ensures compatibility with commercial fiber handling tools, connectors, and protective sleeves.

Write your comment