Quality Control Process

Raw Material Inspection

All incoming materials undergo rigorous testing to ensure they meet our strict specifications before entering production.

- ✓Chemical composition analysis

- ✓Mechanical property testing

- ✓Supplier certification verification

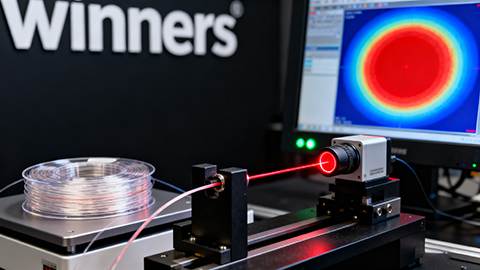

In-Process Quality Checks

Automated and manual inspections are performed at critical stages of production, ensuring that each manufacturing step meets our exacting standards.

- ✓Fiber drawing parameter monitoring

- ✓Coating thickness verification

- ✓Dimensional accuracy checks

Finished Product Testing

Every finished product undergoes comprehensive testing to verify optical performance, mechanical strength, and environmental resistance before packaging.

- ✓Attenuation and bandwidth testing

- ✓Tensile strength verification

- ✓Environmental conditioning tests

Packaging and Shipping Inspection

Final inspections ensure that products are properly packaged and labeled, with all necessary documentation, to prevent damage during transportation.

- ✓Packaging integrity verification

- ✓Label accuracy confirmation

- ✓Documentation completeness check