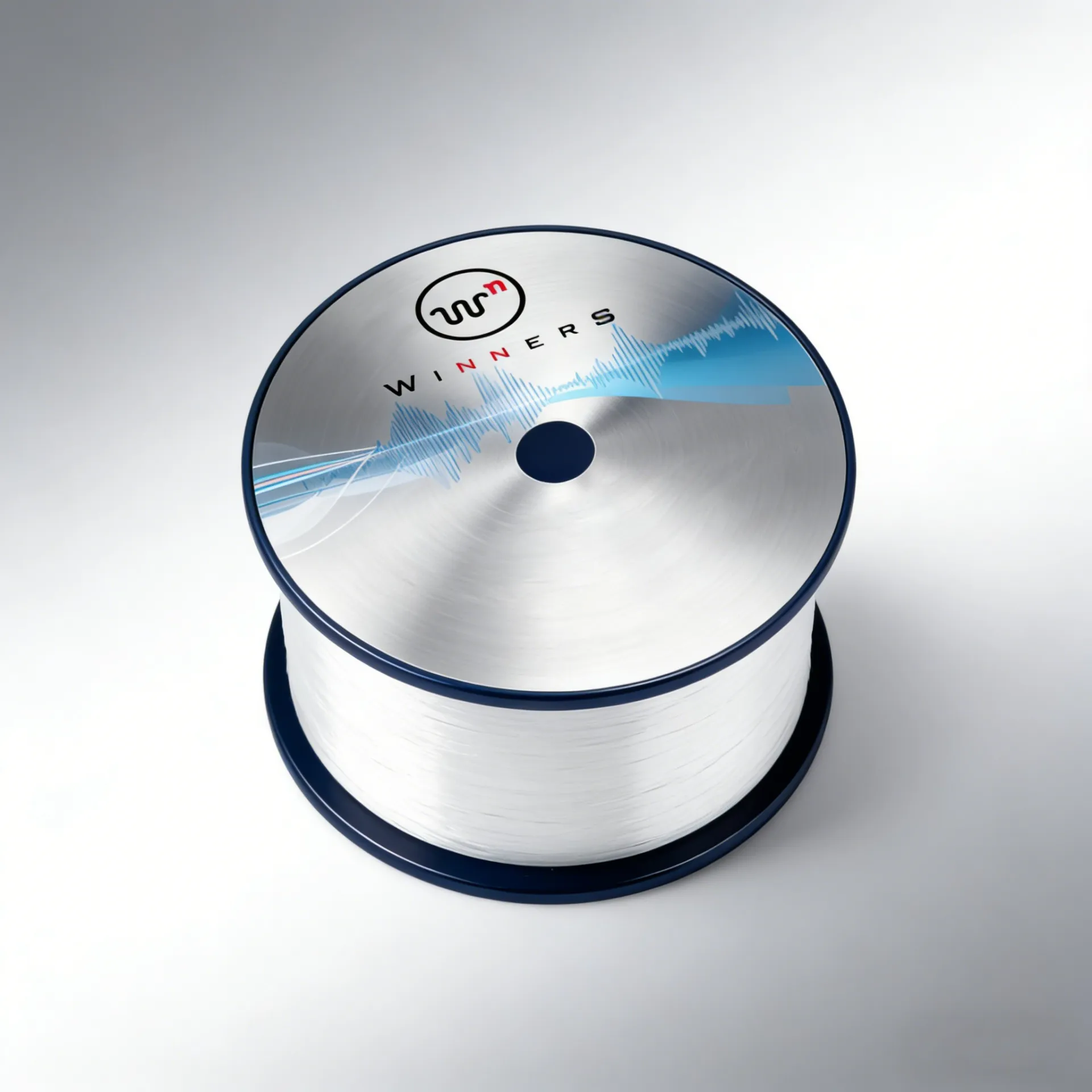

Product Overview

Fabricated using the Modified Chemical Vapor Deposition (MCVD) process, this fiber features a germanosilicate core flanked by two boron-doped stress-applying parts (SAPs) that generate high linear birefringence. This structure effectively preserves the input polarization state over long path lengths, achieving polarization crosstalk of ≤ -25 dB per meter—critical for maintaining high bias stability in closed-loop FOGs.

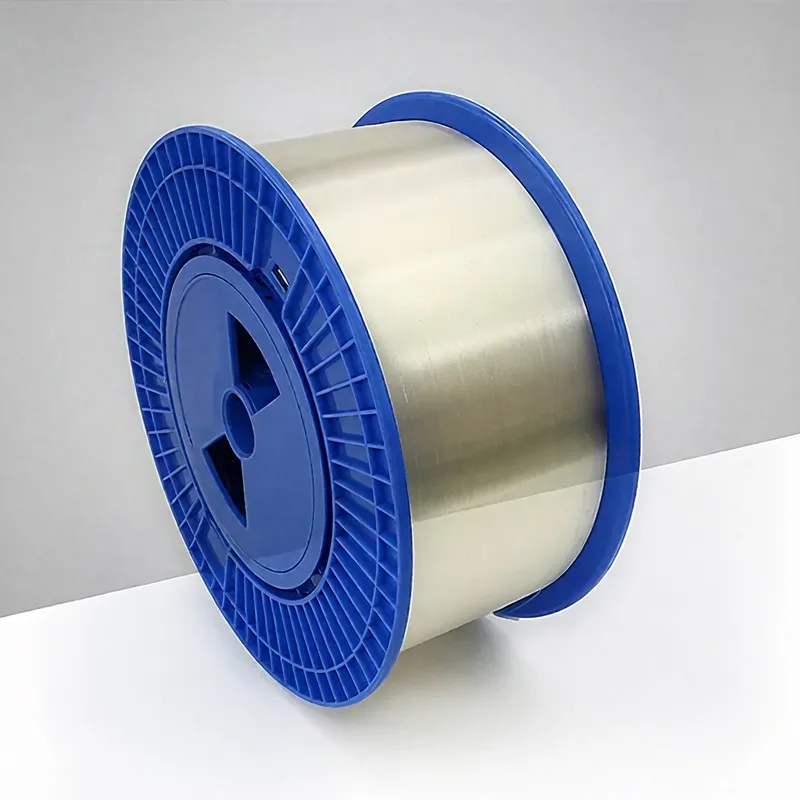

A key innovation is its reduced 135 μm dual acrylate coating—significantly thinner than standard 245 μm fibers—enabling tighter coil winding densities without microbending losses. This makes it ideal for aerospace-grade inertial navigation systems where size, weight, and performance are paramount. Despite its slim profile, the fiber maintains ≥100 kpsi proof tension and excellent geometric uniformity for consistent splicing yield.

Technical Specifications

| Brand Name | Winner |

| Model Number | PM1310-80-6.0/135 |

| Fiber Type | Panda-Type Polarization-Maintaining Single-Mode Fiber |

| Operating Wavelength | 1310 nm |

| Attenuation | ≤0.8 dB/km @1310 nm |

| Mode Field Diameter | 6.0 ± 0.5 μm @1310 nm |

| Cut-off Wavelength | 1100–1270 nm |

| Cladding Diameter | 125 ± 1 μm |

| Coating Diameter | 135 ± 5 μm |

| Polarization Crosstalk | ≤ -25 dB per meter @1310 nm |

| Bow (Shoot Length) | ≤ 3.0 mm per meter |

| Tension Screening Level | ≥100 kpsi |

| Manufacturing Process | Modified Chemical Vapor Deposition (MCVD) |

| Key Performance | High geometric uniformity for low splicing loss (<0.2 dB with axis alignment)

Excellent bending stability down to 10 mm radius

Low welding loss and compatibility with rotational fusion splicers

Stable beat length across temperature cycles (-40°C to +85°C) |

Applications

- High-precision fiber optic gyroscopes (FOGs) for aerospace and defense navigation

- Polarization-maintaining couplers and interferometers for coherent sensing

- Laser diode pigtails requiring polarized output in telecom and lidar systems

- Polarization-sensitive fiber optic current and acoustic sensors

- Test platforms for quantum optics and photonic integrated circuits

Integration Guidance

For optimal polarization extinction ratio (PER), align the slow axis (indicated by SAP orientation) during splicing using a rotational fusion splicer. Maintain bend radii >10 mm to avoid induced birefringence distortion. The 135 μm thin coating reduces coil volume by ~45% compared to standard 245 μm fibers, making it ideal for miniaturized inertial measurement units (IMUs).

Write your comment