Product Overview

Built on a robust MCVD platform, this fiber incorporates boron-doped stress-applying parts (SAPs) symmetrically positioned around a germanosilicate core to generate high linear birefringence. It achieves exceptional polarization crosstalk of ≤ -35 dB over 2 meters—translating to a polarization extinction ratio (PER) >25 dB in practical device assemblies—ensuring signal fidelity in polarization-sensitive systems.

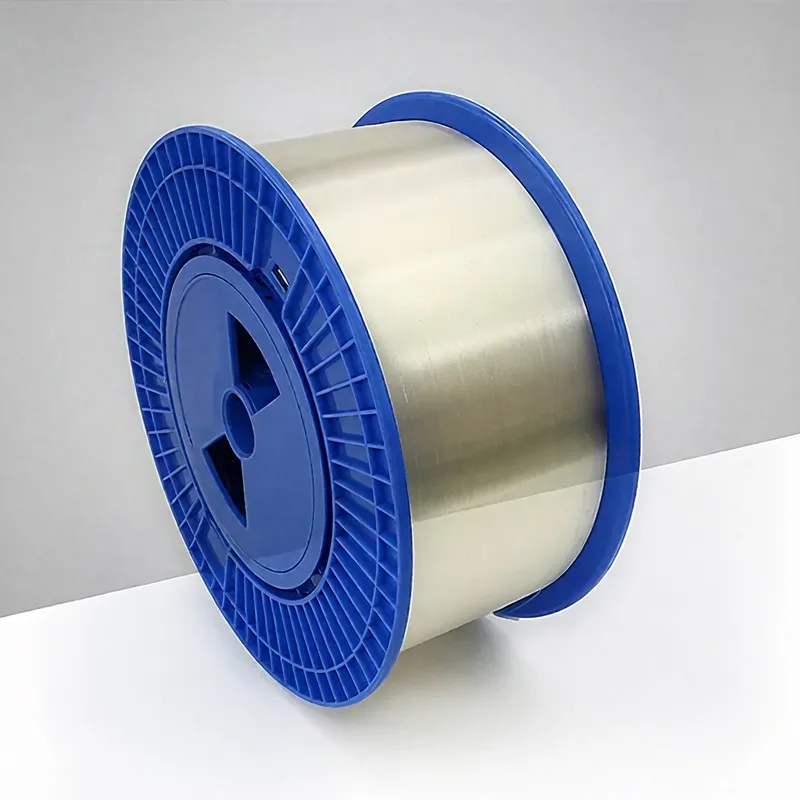

The fiber features a reinforced 165 μm dual-layer acrylate coating, providing enhanced mechanical durability during grinding, polishing, and taper-pulling processes common in pigtail and micro-optic fabrication. Despite its ruggedized design, it maintains low attenuation (≤0.8 dB/km) and excellent geometric uniformity, enabling consistent rotational splicing and high yield in automated production lines.

Technical Specifications

| Brand Name | Winner |

| Model Number | PMW-1310-80-6.0/165 |

| Fiber Type | Panda Polarization-Maintaining Single-Mode Fiber |

| Operating Wavelength | 1310 nm |

| Attenuation | ≤0.8 dB/km @1310 nm |

| Mode Field Diameter | 6.0 ± 0.5 μm @1310 nm |

| Cut-off Wavelength | 1100–1270 nm |

| Cladding Diameter | 125 ± 1 μm |

| Coating Diameter | 165 ± 5 μm |

| Polarization Crosstalk | ≤ -35 dB per 2 meters @1310 nm |

| Bow (Shoot Length) | ≤ 3.0 mm per meter |

| Tension Screening Level | ≥100 kpsi |

| Key Advantages | Superior grindability and surface finish for connector ferrule integration

Excellent taper-pulling consistency for mode-field adapters or sensors

High thermal and mechanical stability across industrial operating conditions

Low splicing loss (<0.15 dB) with axis-aligned fusion splicers |

Applications

- Pigtailed laser diodes requiring polarized output in telecom and sensing

- Polarization-maintaining fiber couplers and splitters for interferometric systems

- Optical isolators, circulators, and modulators with polarization control

- Tapered fiber sensors and nonlinear photonics devices

- Test and calibration standards for polarization-dependent loss (PDL) measurement

Processing Recommendations

For optimal PER retention, align the slow axis (marked by SAP orientation) during splicing using a rotational fusion splicer. The 165 μm thick coating provides excellent resistance to abrasion during polishing and facilitates secure epoxy bonding in metalized packages. Ideal for high-reliability industrial and defense-grade optical subassemblies where long-term polarization stability is non-negotiable.

Write your comment