Product Overview

Fabricated via the Modified Chemical Vapor Deposition (MCVD) process, this panda-type PM fiber integrates two boron-doped stress-applying parts (SAPs) symmetrically positioned around a germanosilicate core to induce strong linear birefringence. The result is exceptional polarization maintenance with crosstalk ≤ -25 dB per meter at 1310 nm, enabling high polarization extinction ratio (PER) in interferometric loops.

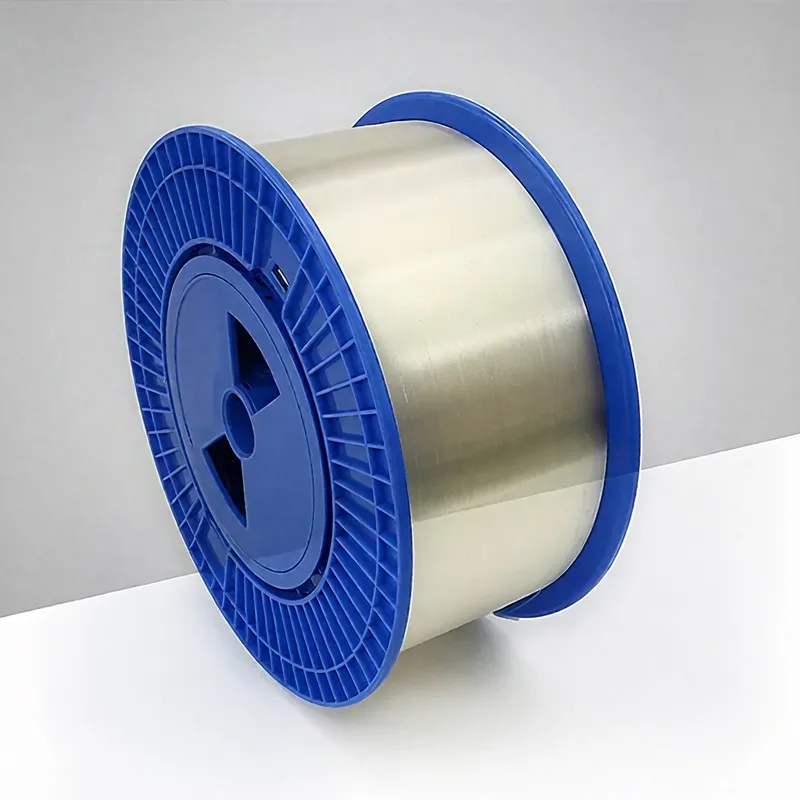

The fiber features a reduced 165 μm dual-layer acrylate coating—ideal for densely wound FOG sensing coils where space and mass are critical. Despite its thin coating, it maintains ≥100 kpsi proof tension screening and excellent bending stability, ensuring mechanical robustness during coil winding and long-term operation in dynamic environments.

Technical Specifications

| Brand Name | Winner |

| Model Number | PM1310-80-6.0/165 |

| Fiber Type | Panda-Type Polarization-Maintaining Single-Mode Fiber |

| Operating Wavelength | 1310 nm |

| Attenuation | ≤0.8 dB/km @1310 nm |

| Mode Field Diameter | 6.0 ± 0.5 μm @1310 nm |

| Cut-off Wavelength | 1100–1270 nm |

| Cladding Diameter | 125 ± 1 μm |

| Coating Diameter | 165 ± 5 μm |

| Polarization Crosstalk | ≤ -25 dB per meter @1310 nm |

| Bow (Shoot Length) | ≤ 3.0 mm per meter |

| Tension Screening Level | ≥100 kpsi |

| Manufacturing Process | Modified Chemical Vapor Deposition (MCVD) |

| Key Performance | High geometric uniformity

Low splicing loss with rotational alignment

Excellent coil-winding compatibility

Stable birefringence under thermal cycling |

Applications

- Fiber optic gyroscopes (FOGs) for aerospace, navigation, and stabilization systems

- Polarization-maintaining couplers and interferometers

- Laser diode pigtails requiring polarized output

- Fiber-based current and magnetic field sensors

- Test and measurement setups for polarization-dependent devices

Handling & Integration Notes

For optimal performance in FOG applications, maintain consistent winding tension and avoid sharp bends (<10 mm radius). Use a rotational fusion splicer to align the slow axis (marked by SAP orientation) with adjacent components. The thin 165 μm coating reduces coil volume by ~30% compared to standard 245 μm fibers, but requires careful handling to prevent microcracking during stripping.

Write your comment